Silo Level Indicator

Knowing the material level inside a silo is key to preventing overfilling, under-feeding or unsafe conditions. A silo level indicator system provides accurate feedback on high and low level conditions, enabling automatic control of refilling, batch feeding and safe operation of silos storing cement, fly-ash or filler.

WorkIng PrIncIple

Level indicators use various technologies – paddle, vibrating fork, rotary disc, or capacitive sensors – to detect the presence or absence of material at predetermined points inside the silo. When the level changes, the sensor sends a signal to the control system which can trigger filling, stop filling, or alert maintenance.

Advantages & Features

* Ensures safe and reliable silo operation by preventing overfill or run-out.

* Suitable for fine powders like cement and fly-ash as well as granules.

* Compact sensors, low maintenance, long life in dusty environments.

* Integrates with batching control systems (PLC).

ApplIcatIons

Used in cement silos of ready-mix concrete plants, fly-ash storage, filler storage, and any bulk material storage where level detection is required. Also used in hoppers feeding screw conveyors or belt feeders.

TechnIcal SpecIfICatIons

Sensor types: vibrating, paddle, rotary.

Voltage: 24 V DC (typical) or 220 V AC depending on model.

Process temperature: −20 °C to +85 °C.

Housing: IP65 or better.

📞 Request a Quote

Don’t risk overfill or under-feeding. Choose our level indicators designed for cement silos and integrate with your automation system.

Or Call Us at

+90-546-726-06-06 (Whatsapp, Telegram)

Silo Top Filter

High-efficiency cement silo top filters prevent dust emissions during loading. Durable, easy to maintain, and suitable for all concrete batching plants & cement storage.

Silo Pressure Relief Valve

Reliable pressure relief valve for cement silos. Prevents overpressure, ensuring safe loading operations and long silo life.

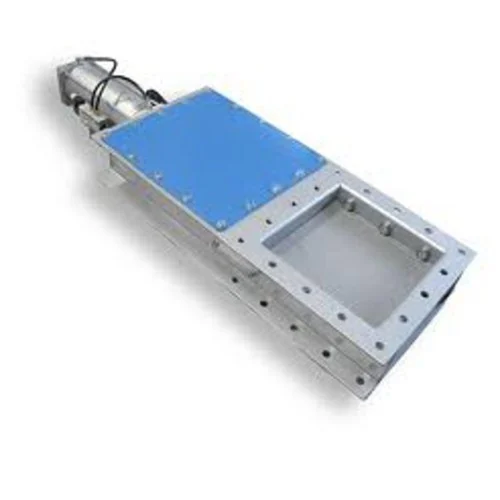

Butterfly Valve

High-quality butterfly valves for cement silos. Ensure smooth material flow and airtight sealing for concrete batching plants.