Silo Air Pad

In many cement silos, fine powder material tends to cling or hang-up in the hopper or cone area, leading to uneven discharge or blockages. An air pad is installed on the inner cone wall and creates a thin air cushion that reduces friction and supports smooth material movement. This improves discharge reliability and reduces manual cleaning.

WorkIng PrIncIple

When the silo air pad is activated, compressed air is distributed beneath a perforated or porous membrane section integrated into the cone surface. This air cushion reduces contact between the material and the silo wall, enabling the material to slip and flow downwards under gravity. Over time this reduces build-up and promotes free flow.

Advantages & Features

* Enhances silo discharge speed and reliability.

* Low energy consumption compared to vibration systems.

* Minimal maintenance since no moving parts inside the material zone.

* Suitable for fine cement powders and fillers in storage silos.

ApplIcatIons

Ideal for cement silos, filler silos and fly-ash storage systems in concrete plants, mortar plants and bulk storage facilities. Particularly useful when material flow issues are frequent.

TechnIcal SpecIfICatIons

Operating air pressure: 0.2-0.6 bar for fluidisation.

Membrane material: PTFE, polyurethane or epoxy-lined rubber.

Suitable temperature range: −20 °C to +70 °C.

📞 Request a Quote

Optimize your cement silo discharge with our air pad systems — contact us for layout advice and sizing.

Or Call Us at

+90-546-726-06-06

(Whatsapp, Telegram)

Silo Top Filter

High-efficiency cement silo top filters prevent dust emissions during loading. Durable, easy to maintain, and suitable for all concrete batching plants & cement storage.

Silo Pressure Relief Valve

Reliable pressure relief valve for cement silos. Prevents overpressure, ensuring safe loading operations and long silo life.

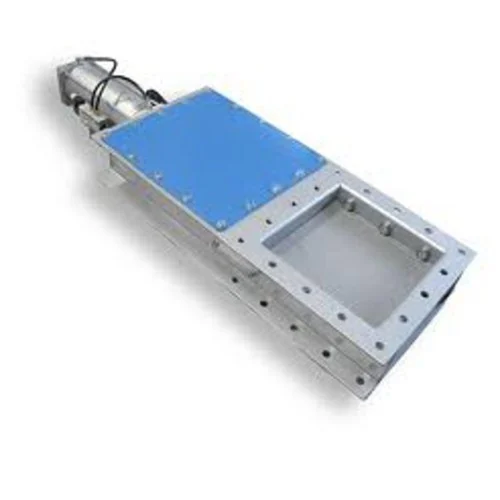

Butterfly Valve

High-quality butterfly valves for cement silos. Ensure smooth material flow and airtight sealing for concrete batching plants.