Silo Fluidisation Nozzle

Flow problems such as bridging or rat-holing inside cement silos or hoppers can cause material blockages and downtime. The silo fluidisation nozzle is a simple yet effective component used to fluidize or mobilize the stored material by introducing a controlled air flow at the silo cone or hopper walls. This keeps the material flowing smoothly into the discharge equipment.

WorkIng PrIncIple

Silo fluidisation nozzle are installed at the cone or walls of the silo and introduce bursts or continuous low pressure air to reduce friction between the material and silo surfaces. This loosens compacted material and ensures it moves toward the discharge outlet. The compressed air comes from the plant air network and is controlled via valves or PLC systems.

Advantages & Features

* Prevents flow stoppages, bridging and rat-holing of powders.

* Simple installation and low maintenance.

* Compatible with dusty, abrasive cement environments.

* Enhances material flow reliability and reduces manual cleaning.

ApplIcatIons

Used in cement silos, fly-ash silos and filler hoppers in concrete plants, dry-mix plants, mortar plants and other bulk material storage systems. Especially effective for fine powders and high-volume storage.

TechnIcal SpecIfICatIons

Operating air pressure: typically 4-6 bar.

Nozzle material: brass, stainless steel or aluminium.

Suitable temperature range: −20 °C to +80 °C.

📞 Request a Quote

Improve your material flow and reduce downtime with our reliable air nozzles designed for cement silos. Contact us for recommended layout and sizing.

Or Call Us at

+90-546-726-06-06 (Whatsapp, Telegram)

Silo Top Filter

High-efficiency cement silo top filters prevent dust emissions during loading. Durable, easy to maintain, and suitable for all concrete batching plants & cement storage.

Silo Pressure Relief Valve

Reliable pressure relief valve for cement silos. Prevents overpressure, ensuring safe loading operations and long silo life.

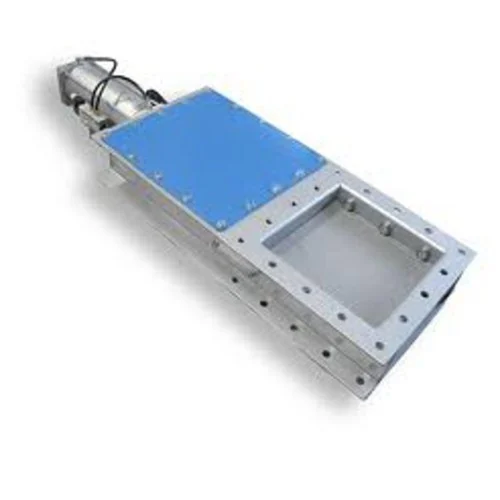

Butterfly Valve

High-quality butterfly valves for cement silos. Ensure smooth material flow and airtight sealing for concrete batching plants.