Cement Silo Top Filter

Cement silo top filters are designed to prevent dust emissions during cement loading operations in concrete batching plants. They ensure clean air discharge while trapping fine cement particles inside the silo. This system enhances environmental safety and protects working conditions.

WorkIng PrIncIple

As cement is pneumatically transferred into the silo, air pressure builds up. The filter separates dust from the air through high-performance cartridges. An automatic pulse-jet system periodically cleans the filter elements to maintain consistent performance.

Advantages & Features

* High dust collection efficiency

* Automatic cleaning without stopping operation

* Compact, lightweight design for easy installation

* Long-lasting filter elements

* Eco-friendly, low-maintenance solution

ApplIcatIons

* Concrete batching plants

* Cement and fly ash silos

* Bulk powder storage systems

TechnIcal SpecIfICatIons

Filtration area: 10–24 m²

Airflow: up to 1,500 m³/h

Material: Powder-coated steel

Cleaning system: Pulse-jet

Filter media: Polyester cartridge

📞 Request a Quote

Looking for a reliable silo top filter ?

Contact us to get a quotation or customized design for your project.

Or Call Us at

+90-546-726-06-06

(Whatsapp, Telegram)

Silo Pressure Relief Valve

Reliable pressure relief valve for cement silos. Prevents overpressure, ensuring safe loading operations and long silo life.

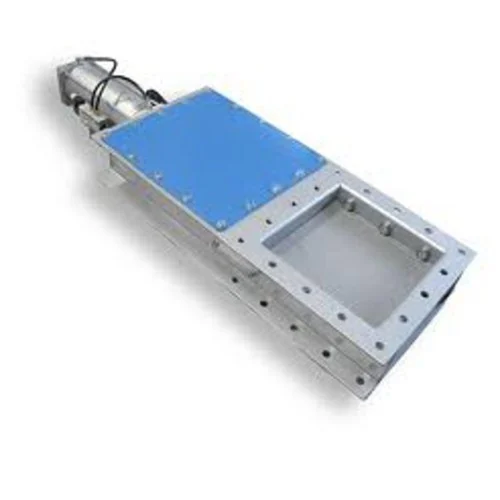

Butterfly Valve

High-quality butterfly valves for cement silos. Ensure smooth material flow and airtight sealing for concrete batching plants.