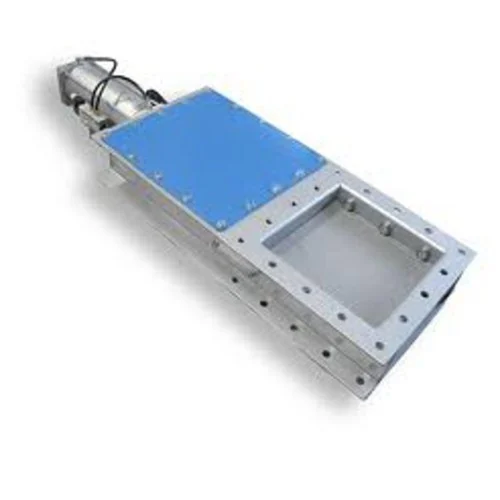

Slide Gate Valve

Reliable control of material discharge from a cement silo is fundamental for batching accuracy and plant safety. The slide gate valve offers a heavy-duty solution for opening and closing the outlet of silos or hoppers, ensuring full shut-off or controlled feed into screw conveyors or weigh hoppers.

WorkIng PrIncIple

The slide gate valve features a flat plate (the “gate”) that slides across the outlet opening, either manually or via pneumatic/hydraulic actuation. When closed, it provides tight shut-off; when open, it allows bulk material to pass through. The design ensures minimal leakage and is suitable for high-abrasion materials like cement and fly-ash.

Advantages & Features

* Full shut-off capability with minimal dust escape.

* Heavy-duty construction suitable for abrasive powders.

* Manual, pneumatic or hydraulic actuation options.

* Easy maintenance with replaceable wear plates.

ApplIcatIons

Used under cement silos, filler silos, and storage bunkers to control discharge into feeders, conveyors or trucks. Common in ready-mix plants, asphalt plants, dry mix plants and precast facilities.

TechnIcal SpecIfICatIons

Gate size: DN150 to DN600 or larger depending on system design.

Body and gate material: carbon steel, sometimes lined for abrasion resistance.

Actuation: manual lever, pneumatic cylinder, or hydraulic ram.

📞 Request a Quote

For precision discharge control and tight shut-off in your batching plant, explore our slide gate valve range engineered for cement systems.

Or Call Us at

+90-546-726-06-06

(Whatsapp, Telegram)

Silo Top Filter

High-efficiency cement silo top filters prevent dust emissions during loading. Durable, easy to maintain, and suitable for all concrete batching plants & cement storage.

Silo Pressure Relief Valve

Reliable pressure relief valve for cement silos. Prevents overpressure, ensuring safe loading operations and long silo life.

Butterfly Valve

High-quality butterfly valves for cement silos. Ensure smooth material flow and airtight sealing for concrete batching plants.