Valve Manual Lever

While many bulk material systems rely on automated control, a manual lever remains essential for emergency operation, maintenance or backup situations. In cement silos and feeding systems, the manual lever offers a straightforward method to operate butterfly valves or slide gates when automation is unavailable or fails.

WorkIng PrIncIple

The manual lever is mechanically linked to the valve shaft, enabling an operator to physically turn or slide the valve to open or close. The lever provides mechanical advantage and clear indication of valve position. It is designed for heavy-duty use in dusty and abrasive environments.

Advantages & Features

* Direct manual control during maintenance or power failure.

* Rugged construction designed for cement handling environments.

* Clear visual position indicator.

* Compatible with various valve sizes (butterfly, slide gate) in concrete and bulk material plants.

ApplIcatIons

Used in concrete batching plants, asphalt plants and bulk material storage facilities where manual or backup operation of discharge valves is required.

TechnIcal SpecIfICatIons

Lever length: depends on valve size (e.g., 350–800 mm).

Material: carbon steel with corrosion-resistant finish.

Operating temperature: −20 °C to +60 °C.

📞 Request a Quote

For dependable manual control of your valve systems in cement plants, request our manual lever assemblies and link-plates.

Or Call Us at

+90-546-726-06-06

(Whatsapp, Telegram)

Silo Top Filter

High-efficiency cement silo top filters prevent dust emissions during loading. Durable, easy to maintain, and suitable for all concrete batching plants & cement storage.

Silo Pressure Relief Valve

Reliable pressure relief valve for cement silos. Prevents overpressure, ensuring safe loading operations and long silo life.

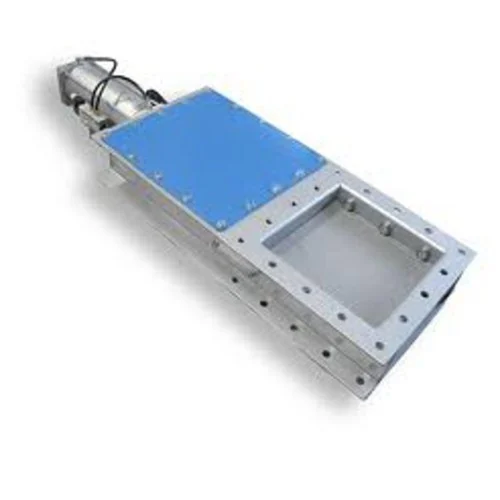

Butterfly Valve

High-quality butterfly valves for cement silos. Ensure smooth material flow and airtight sealing for concrete batching plants.