Vibration Motor

To maintain continuous discharge of cement and other fine powders, material accumulation and bridging inside silos and hoppers must be prevented. A vibration motor mounted on the outer cone or hopper body provides periodic vibration that loosens compacted material and supports reliable flow.

WorkIng PrIncIple

The vibration motor generates cyclic vibration through an eccentric weight mounted on the motor shaft. When mounted to the structure (silo cone or hopper body), the vibration transfers to the powder material inside, reducing friction and preventing build-up of material. The motor is designed to work in dusty, abrasive and high-load conditions typical of cement silos.

Advantages & Features

* Prevents material bridging, rat-holing and blockages.

* Hard-wearing design for long-term duty in harsh environments.

* Minimal maintenance (sealed bearings, robust housing).

* Variable frequency drive (VFD) compatible for adjustable vibration.

ApplIcatIons

Used at the discharge cones of cement silos, fly-ash silos, filler bunkers, and dry-mix plants to ensure smooth material flow. Ideal for fine powders prone to compacting.

TechnIcal SpecIfICatIons

Frequency: 50/60 Hz or variable via VFD.

Motor power: e.g., 0.25-2.2 kW depending on hopper size.

Operating temperature: −20 °C to +60 °C.

Protection rating: IP66 or better.

📞 Request a Quote

Eliminate discharge problems in your cement silos — choose our vibration motors designed for high-duty bulk material systems.

Or Call Us at

+90-546-726-06-06

(Whatsapp, Telegram)

Silo Top Filter

High-efficiency cement silo top filters prevent dust emissions during loading. Durable, easy to maintain, and suitable for all concrete batching plants & cement storage.

Silo Pressure Relief Valve

Reliable pressure relief valve for cement silos. Prevents overpressure, ensuring safe loading operations and long silo life.

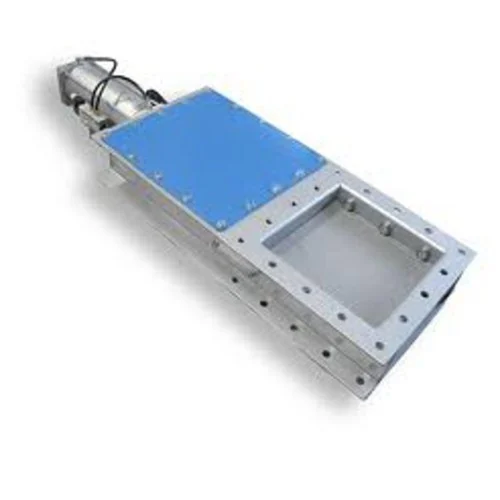

Butterfly Valve

High-quality butterfly valves for cement silos. Ensure smooth material flow and airtight sealing for concrete batching plants.